Unidirectional ball bearings are used to transmit torque in one direction, allowing for free relative movement in the other direction.

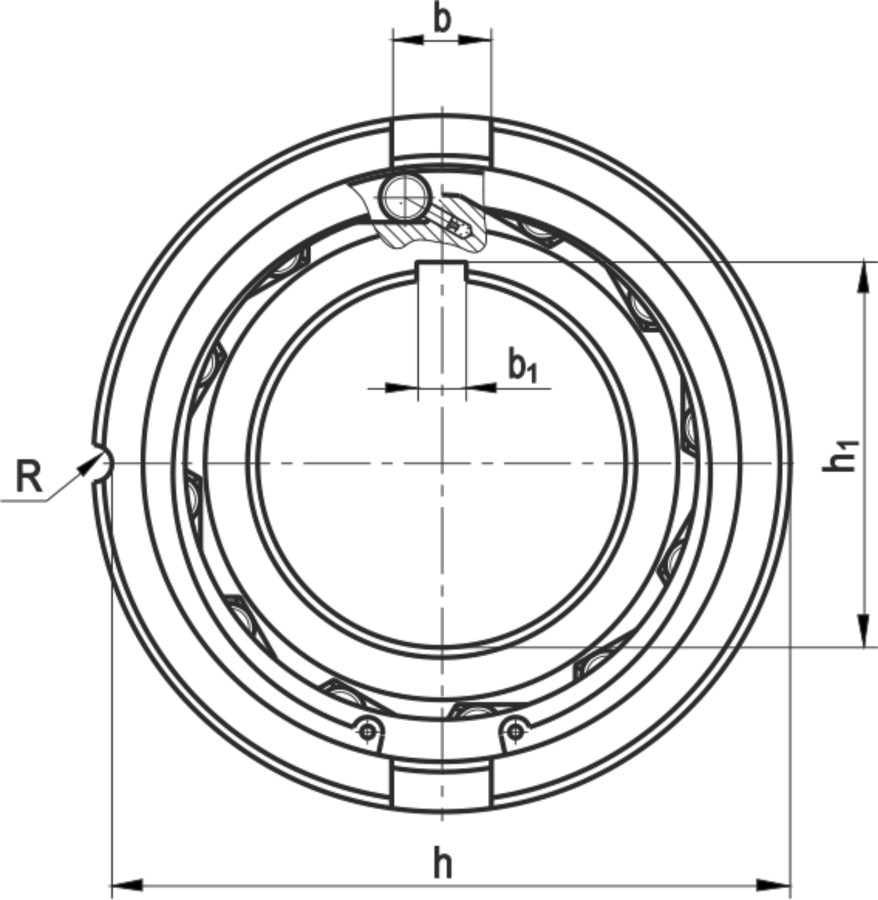

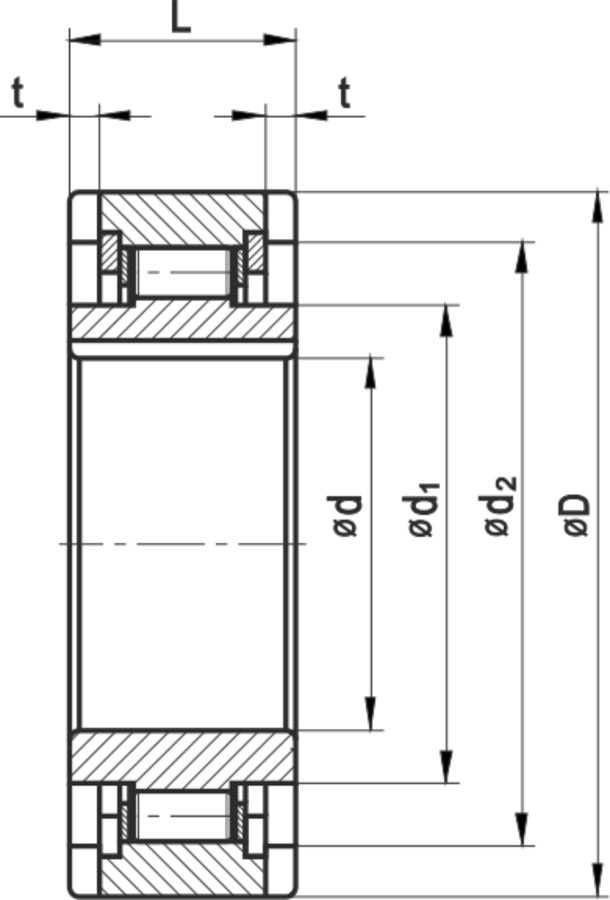

| STATEMENT | Dimensions |

Mo |

||||||||||

|

d |

D | L | d1 | d2 | b | h | b1 | h1 | t | R | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Nm | |

| OŁT 023.1. | 8 | 24r6 | 8 | 11 | 20 | - | - | 2 | 9 | - | - | 2 |

| OŁT 023.2. | 12 | 35n6 | 13 | 18,5 | 30 | 4 | - | 4 | 13,8 | 1,5 | - | 6 |

| OŁT 023.11. | 15 | 35r6 | 11 | 21 | 30 | - | - | 5 | 16,2 | - | - | 8 |

| OŁT 023.3. | 15 | 42n6 | 18 | 24 | 36 | 5 | - | 5 | 16,2 | 1,5 | - | 20 |

| OŁT 023.4. | 20 | 47r6 | 14 | 28 | 42 | - | - | 6 | 21,6 | - | - | 23 |

| OŁT 023.5. | 20 | 52n6 | 21 | 30 | 45 | 6 | - | 6 | 21,6 | 1,8 | - | 50 |

| OŁT 029.25/55A. | 25 | 55+ 0,015 |

17 | 34 | 47 | - | 53,5 | 5 | 27,3 | - | 1,5 | 80 |

| OŁT 023.6. | 25 | 62n6 | 24 | 36,5 | 52 | 8 | - | 8 | 27 | 2,3 | - | 80 |

| OŁT 023.9. | 30 | 62r6 | 16 | 40,4 | 55 | - | - | 8 | 32 | - | - | 55 |

| OŁT 023.7. | 30 | 72r6 | 27 | 30 | 62 | 10 | - | 8 | 32 | 2,6 | - | 120 |

| OŁT 023.10. | 35 | 72r6 | 17 | 47,4 | 63 | - | - | 10 | 37,4 | - | - | 90 |

| OŁT 023.8. | 35 | 80n6 | 31 | 48 | 70 | 12 | - | 10 | 37,4 | 3,6 | - | 150 |

| SPS 40 | 40 | 80r6 | 18 | 53,5 | 70 | - | - | 12 | 42,3 | - | - | 120 |

| SP 40 | 40 | 90n6 | 33 | 54,5 | 78 | 12 | - | 12 | 42,3 | 3,6 | - | 230 |

Their action consists of wedging rollers between the outer ring and the appropriately shaped (so-called “star”) inner ring. The working surfaces of both rings form a self-locking angle. The rollers are individually pressed against the ring raceways by means of springs and tappets, which allows for immediate action, and the “dead angle” resulting only from the elastic deformation of the clutch components is practically zero.

In order to ensure the proper working conditions for the coupling, it is required that the coupling is set by means of radial ball bearings, as the coupling itself is not a bearing.

Unidirectional couplings are not designed to transmit any axial (longitudinal) forces, either in service or during assembly.

As standard, the couplings are designed to operate at a frequency of up to 60 cycles/min. The use of higher frequencies is conditioned by a number of factors such as inertia of rotating masses, lubrication conditions, etc. The use of higher frequencies is conditioned by a number of factors such as the inertia of rotating masses, lubrication conditions, etc.

The service life of the couplings, determined by - 107 cykli, the number of activation cycles, which is an average of 107 cycles, depends on the operating conditions, the nature of the operation (e.g. impact load) and the length of free running.

Lubrication. In conditions of prolonged free running, at peripheral speeds not exceeding 6 m/s, it is recommended to use lubrication of couplings with low viscosity oils in the range from 8.33 cSt to 59.34 cSt at 40°C. At low speeds, low viscosity plastic greases can be used to fill up to 30% of the free space.

No maintenance is required for the clutch other than lubrication.

The operating temperature of the couplings should not exceed 120°C.

Installation conditions: housing H7, shaft h6 h6

Application:

In motor vehicles, agricultural machinery, assemblies and mechanisms, e.g. packaging machines, etc.

Delivery status:

Not lubricated.

Protected by maintenance oil, packed in corrosion inhibited anti-corrosion paper.