Over the course of our 50 years on the market, we have performed repairs and modernizations of several hundred production machines.

From the very beginning, we have specialized in the bearing industry, while also providing services for the automotive, casting, tooling and tyre industries. We repair and modernize metalworking machines and machines for serial production.

We specialize in metal grinders. We have many years of experience in repairing the following types of machines: Centreless grinders, Hole grinders, Main carriageway grinders, Auxiliary carriageway grinders, Front grinders, Shaft grinders, Toothcutting grinders.

We also perform repairs and modernizations of the following types of machines: Finishing machines, Task lathes, Centrifuges, Drilling machines, Deep hole drilling machines, Cockpitting machines, Peelers, Dredgers and other machines for serial production.

We provide repair services as agreed with the customer, such as:

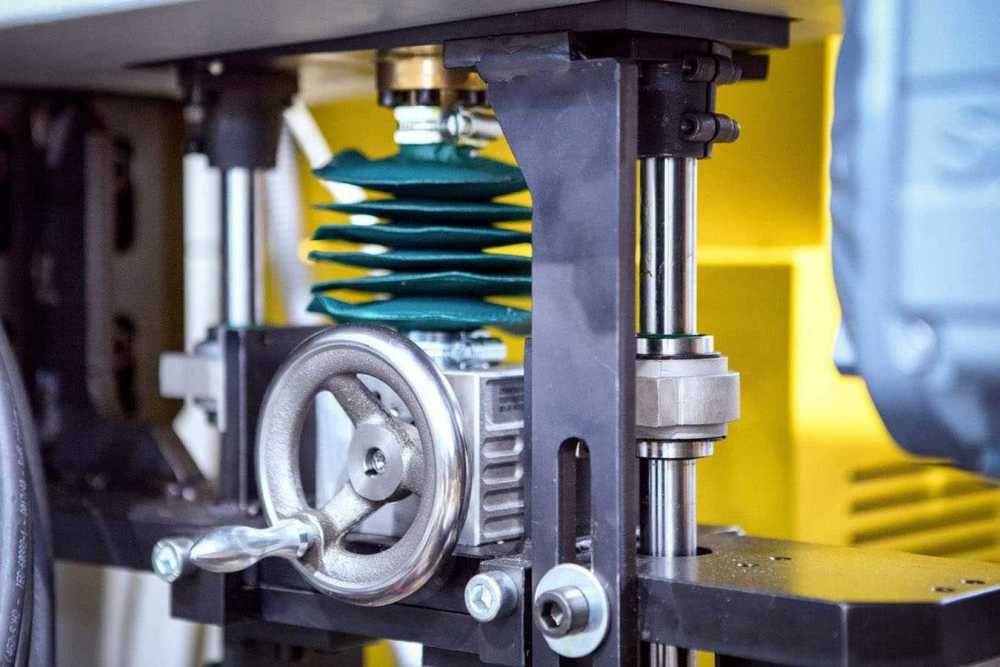

- Regeneration of machine tool components (Headstocks, Diamonds, Supports and others)

- General mechanical overhauls

- Replacement of obsolete technical solutions with modern ones

- Modernization of the control system with the replacement of wiring and control cabinet

Before each overhaul, we carry out a verification of the technical condition of parts and components of the machine by involving a constructor, mechanic, technologist, and often the customer too. We perform repairs according to the recommendations of the report prepared by our construction team.

We refurbish and manufacture parts and subassemblies mostly using our own machines. After the installation and commissioning of the machine, it is collected and qualified for work with the customer’s representatives at our plant.