We specialize in the production of special machines and devices. We deal with every stage of production from consultation with the client, preparation of the mechanical and electrical design, through the execution of elements, construction of electrical cabinets to the assembly and start- up of the machine, and testing at the customer.

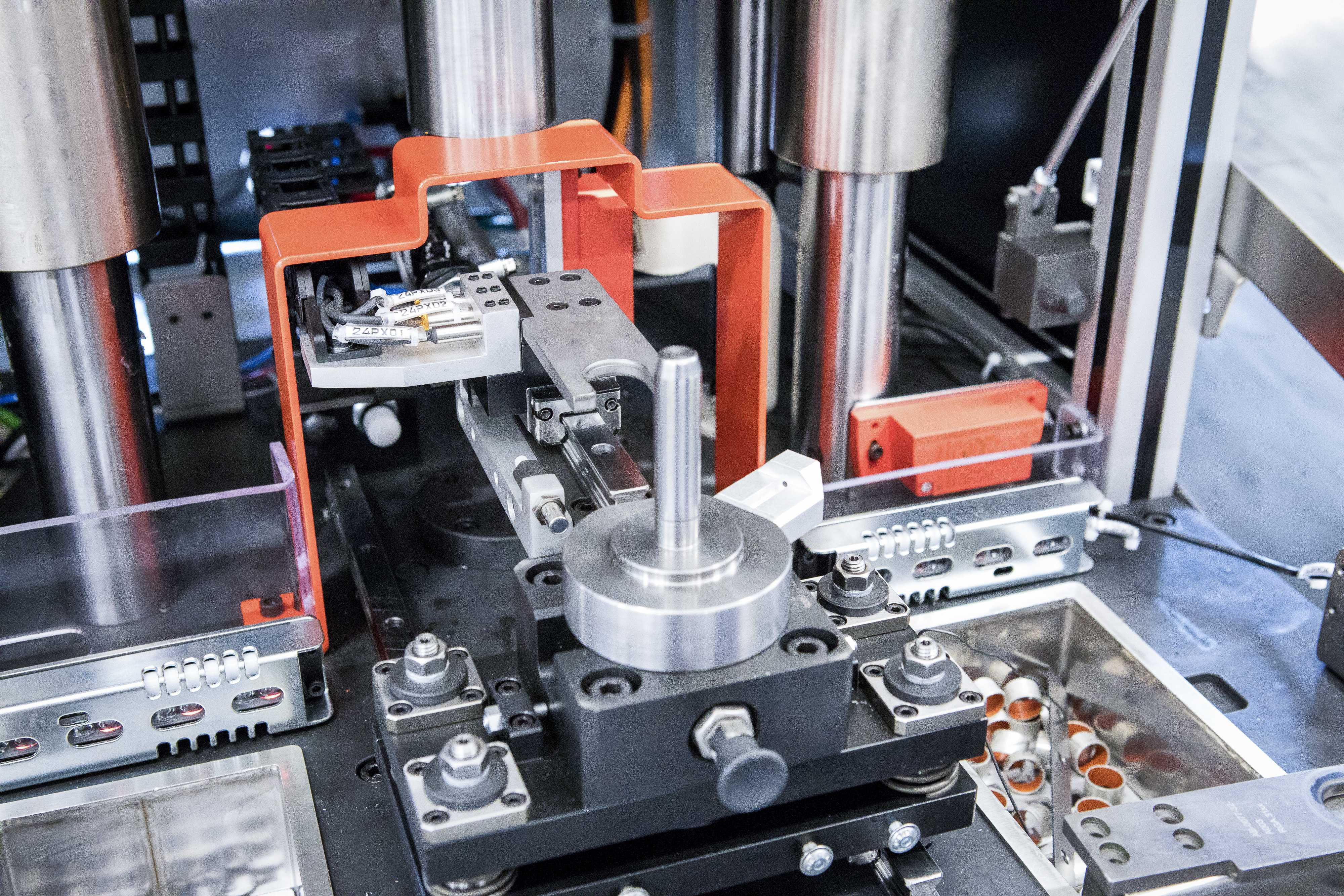

We manufacture devices for manual and semi-automatic work as well as fully automated stations, including specialized test stands.

We operate in the automotive, household appliance, tire, and chemical and bearing industries.

Each device built by us has complete documentation - workplace instructions, electrical, pneumatic, hydraulic diagrams, as well as an EC declaration of conformity and a plate with the CE mark.

The stands are built, depending on the client's needs and requirements, based on FESTO and SMC pneumatics and control by SIEMENS, ALLEN BRADLEY, MITSUBISHI, OMRON and any other specifications meeting the client's requirements.

During assembly, we control the order of operations performed by the operator using pic-to-light systems as well as error-profing or pokayoke elements.

Our test stands are used for pressure tests, flow and weight measurements, vision control and contact or non-contact measurements of critical product parameters. All data is saved on PLC card or in the database.