At ISKRA ZMiŁS, we constantly focus on development.

Our values are experience, innovation and high quality.

Mission

In-depth knowledge of the market, our own production facilities and investment in human potential have helped us to create a brand recognizable in Poland and abroad.

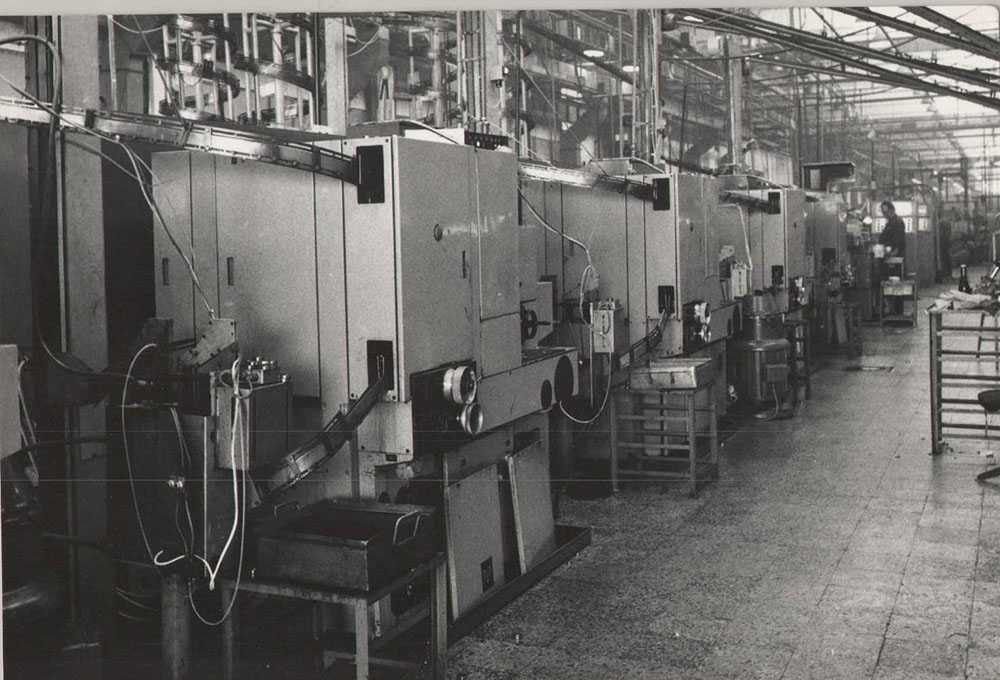

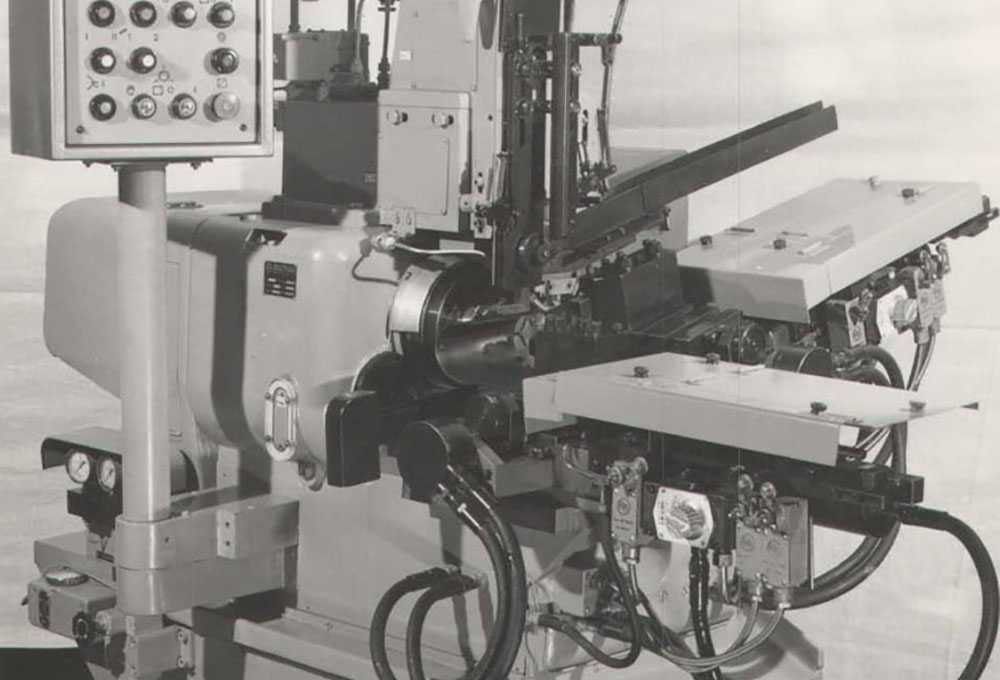

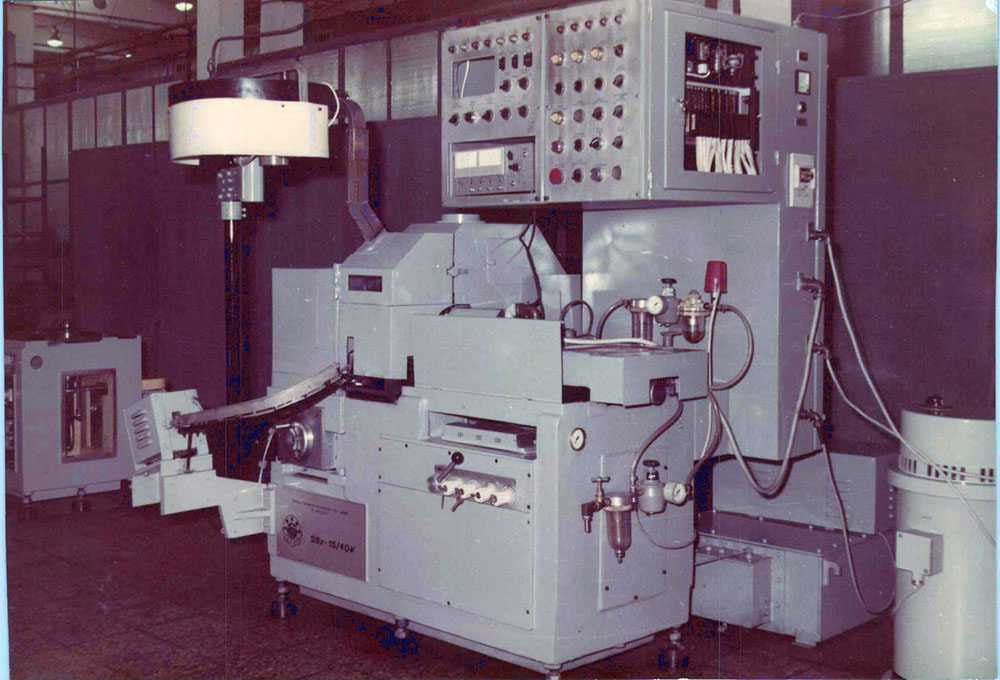

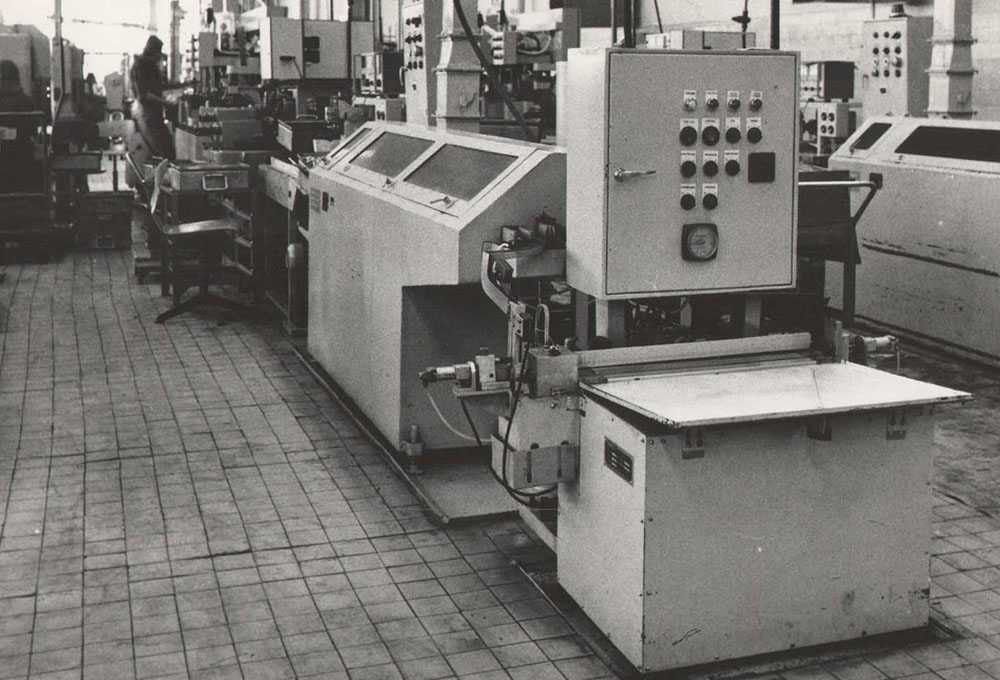

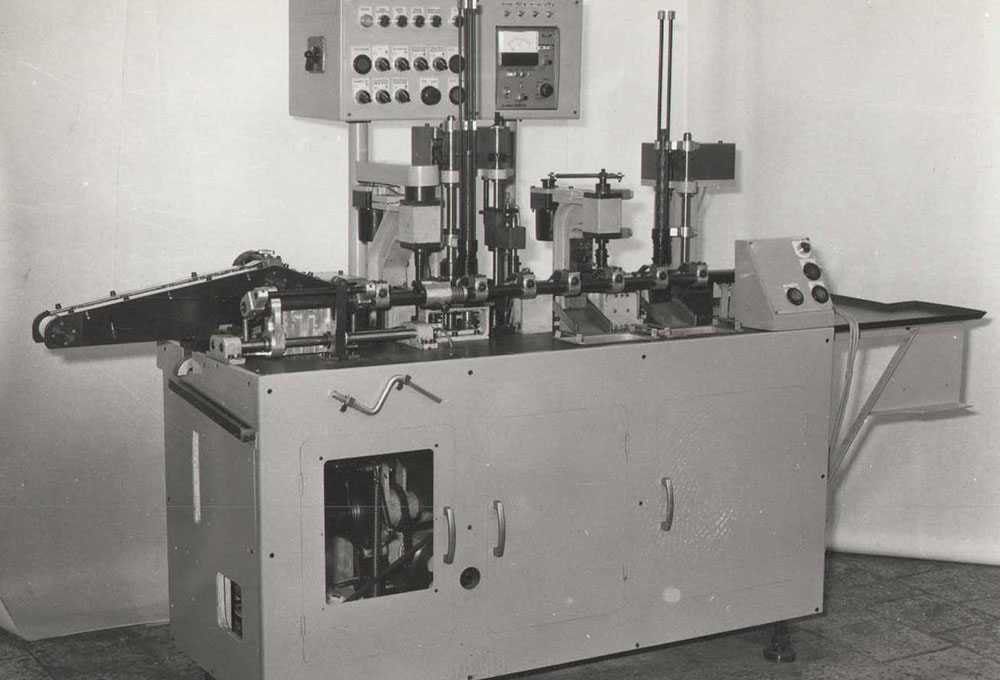

We use our knowledge and over 50 years of experience to provide comprehensive solutions for the design, manufacture, and modernisation of machinery and equipment, special bearing products and machining services. We manufacture and launch devices for various branches of industry based on methods and components used by the most reputable companies in the world.

Our qualified team of engineers design machines and equipment in accordance with international safety standards, taking into account high quality, ergonomics and convenience.

We provide comprehensive solutions and products tailored to our customers’ needs; prepared, developed and manufactured almost entirely within our company.

We provide support at every stage of device development; we have our own design office, technology office, machining department, mechanical and electrical workshop, as well as a team of programmers and engineers.

-

-

-

-

-

-

-

-

-

-

ISKRA ZMiŁS in numbers

40

Specialists

and engineers

50 years old

Experiences

in the machinery industry

100

More than 100 metalworking machines

6000 m2

Surface of production and assembly halls